Modeling and Explaining an Industrial Workforce Allocation and Scheduling Problem

-

05/09/2025

-

NewsNews

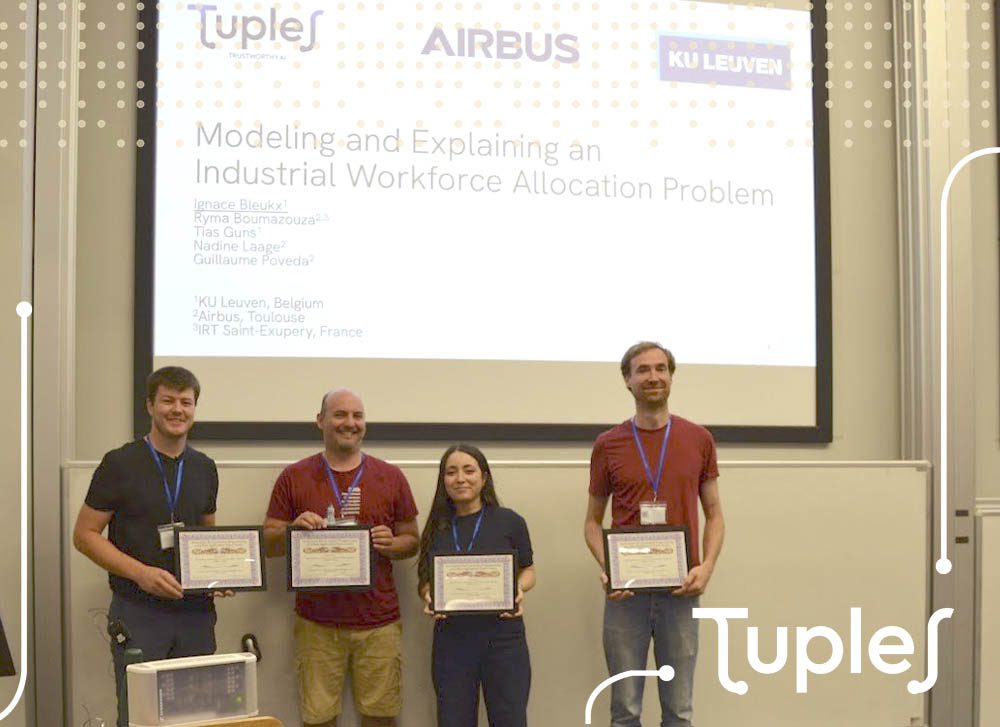

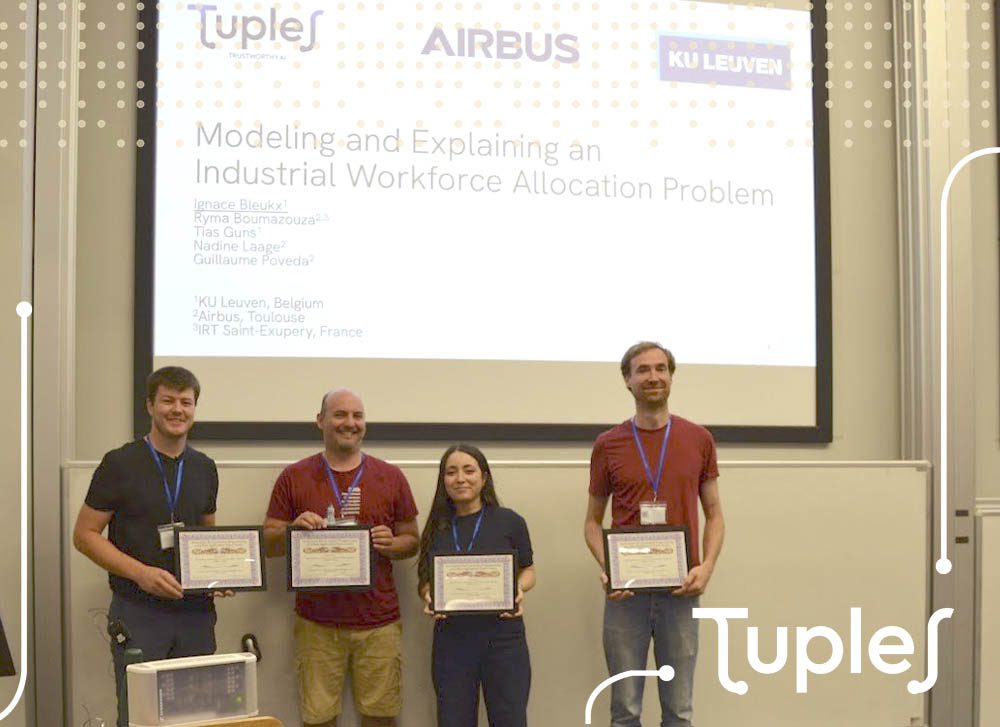

We present an in-depth article on the paper “Modeling and Explaining an Industrial Workforce Allocation and Scheduling Problem” by Ignace Bleukx, Ryma Boumazouza, Tias Guns, Nadine Laage, and Guillaume Poveda, which received the Best Application Paper Award at the 31st International Conference on Principles and Practice of Constraint Programming (CP 2025).

Among the authors, Ryma Boumazouza, Ignace Bleukx, Tias Guns, and Guillaume Poveda are members of the TUPLES consortium, highlighting the project’s contribution to advancing real-world, trustworthy AI for planning and scheduling.

The Challenge: Planning at Scale

Aircraft manufacturing requires hundreds of logistical operations every day, from transporting parts and equipment to loading and unloading cargo.

This activity presents several challenges such as the scale of the problems, the need for fair workload distribution, and the need for methods for mitigating unforeseen disruptions due to technical malfunctions or incompatible weather conditions.

These tasks must be allocated to specialized teams with the right training and equipment, under strict deadlines.

Traditionally, teams of operational planners schedule and allocate tasks manually. This is not only time-consuming, but also vulnerable to disruptions such as:

* Delays in part deliveries

* Technical malfunctions

* Adverse weather conditions

* Unavailability of trained workers

In such cases, planners are forced to revise schedules under extreme time pressure, often dropping tasks or pushing them into the next planning horizon.

The Research: Smarter Models, Fairer Schedules

The paper introduces novel CP models that balance efficiency and fairness in workforce allocation.

Key contributions include:

• Workload Balancing: ensuring a fair distribution of tasks across teams, avoiding overburdening.

• Scalability: solving large instances with hundreds of daily tasks in reasonable time.

• Disruption Handling: using explainable AI methods to detect, explain, and repair infeasible schedules.

Explainability in Action

One of the most innovative aspects of the paper lies in its focus on explainability. When schedules are disrupted, understanding why a plan becomes infeasible is crucial for human operators.

The researchers applied techniques such as:

• Minimal Unsatisfiable Subsets (MUSes): identifying the exact set of constraints that cause infeasibility.

• Minimal Correction Subsets (MCSes): suggesting constraint relaxations that restore feasibility.

This dual approach not only provides planners with insights into the source of disruptions but also offers automated alternatives for repairing the schedule. In practice, this helps planners make faster, better-informed decisions during operational crises.

Impact and Future Directions

The award-winning research demonstrates the feasibility of deploying interactive decision-support systems in real industrial settings.

Such systems would allow planners to:

1. Automatically generate fair, optimized schedules.

2. Understand the causes of disruptions when plans fail.

3. Quickly review and adapt automated alternatives to restore feasibility.

Future work includes:

• Extending the problem from allocation and scheduling to full allocation-and-routing.

• Conducting user studies to evaluate the effectiveness of generated explanations in real planning environments.

• Investigating robust scheduling methods that anticipate disruptions before they occur.

🏆 Why It Matters

This award-winning paper exemplifies the mission of TUPLES: developing trustworthy, robust, and explainable AI systems for planning and scheduling. By combining advanced CP modeling with explainability techniques, the research paves the way for more resilient and human-centered decision support in critical industrial domains.

📖 Read the full paper here