Beluga™ AI Challenge

The Challenge has been a remarkable test for researcher and practitioner in sequential decision making interested in trustworthy AI. Participants have engaged with real-world industrial use cases and network with leading researchers and experts.

The Problem

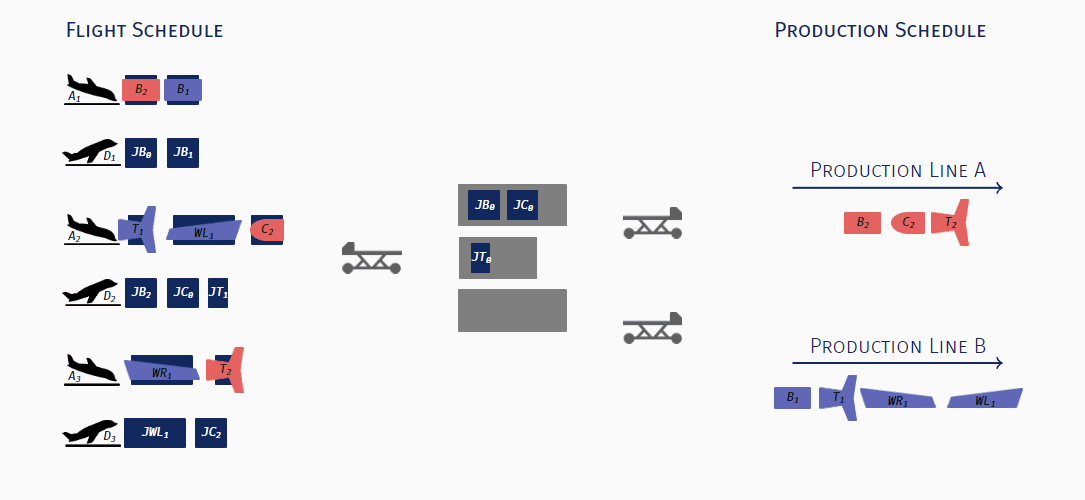

The competition challenge was based on a logistic planning problem proposed by Airbus. It dealt with the storage and management of cargo transported by Airbus Beluga XL aircrafts. Those bring aircraft parts that need to be pushed to – or pulled from – a rack system that works as a bidirectional multi queue system.

Aircraft parts are held on jigs, which can slide and be stored on the racks. Trailers are used as special moving racks to transfer the jigs between the Beluga and the fixed racks. When the aircraft parts are sent to the production lines, they transit to hangars where cranes remove the parts from the jigs. The parts are then sent to production and the jigs return empty to the rack system.

The racks can contain several jigs in sequence, but only the jigs which are at the edges of the racks (either factory side or Beluga side) can be pulled out. This might require swapping jigs located at the rack edges to other racks in order to free the pass to jigs which are strictly inside the racks.

When the Beluga lands at the production site, 2 high-level tasks must be performed:

● unloading the parts (held on jigs) and storing them in the rack system;

● unstoring empty jigs from the rack system and loading them into the Beluga.

Between two Beluga flights, 3 high-level tasks must be considered:

● unstoring parts held on jigs from the rack system and sending them to the production lines via the craning hangars;

● sending back empty jigs from the craning hangars to the rack system;

● [optionally] swapping the jigs which are at the edges of the racks (either factory side or Beluga side) from one rack to another, in order to free the pass to jigs which are strictly inside the racks.

The Challenges

We have been searching for the plan of minimum length among all the plans that reach the goal.

Therefore, two separate scalability challenges have been proposed:

- Scalability challenge [Deterministic]

In the deterministic version of the problem, we do not consider any uncertain event. The problem consists in finding a plan, i.e. a sequence of actions, which reaches a goal consisting in the 3 following conditions to be met:

– all parts coming in the Beluga flights are unloaded in the required order and stored in the rack system

– all parts to be consumed by the production lines are sent to production in the required order

– all empty jig types to be carried by outgoing Beluga flights are sent to the Beluga in a required order. - Scalability challenge [Probabilistic]

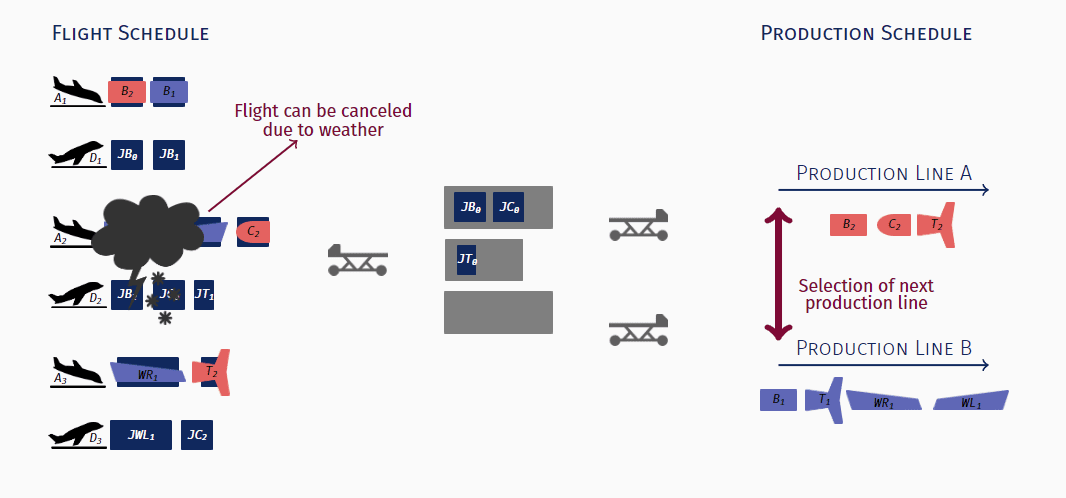

In addition, for the probabilistic version we consider uncertainties in the flight arrival times, which can alter the sequence in which jigs become available. In this case, the problem consists in finding a policy, i.e. a mapping from states to actions, whose execution optimises the evaluation metrics.

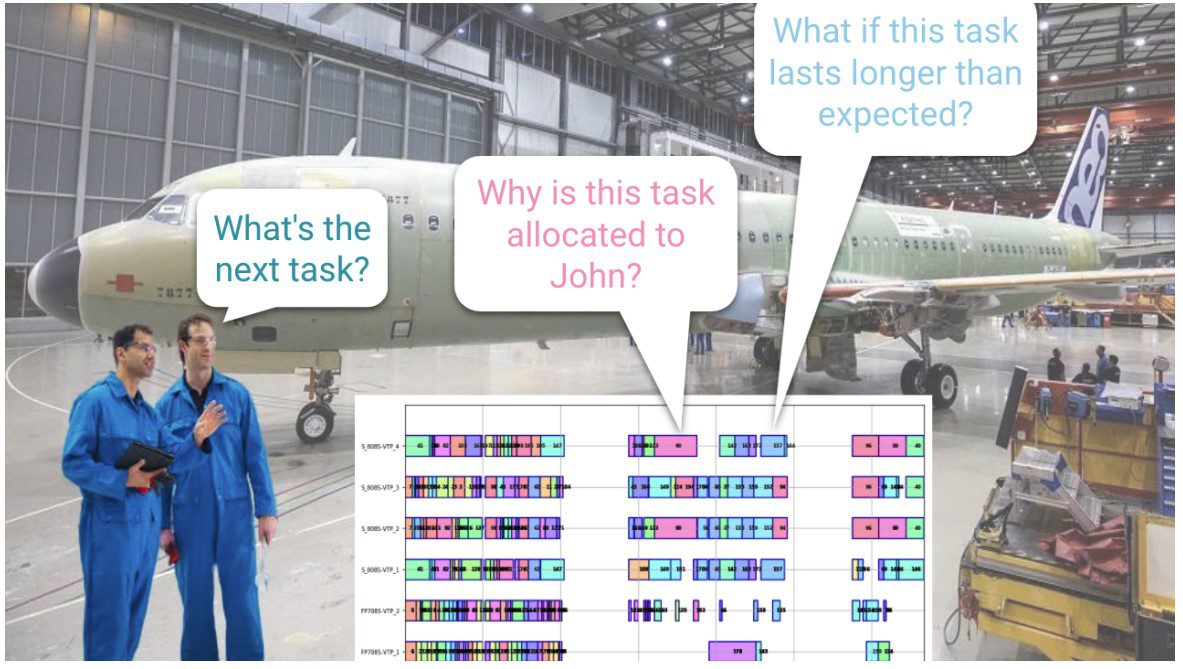

In addition, planning and Scheduling relies on expert (human) planners, and new approaches, such as those featured within the Scalability Challenge, must be accepted and trusted before those planners will use them. Explainability is a key element of this. For this reason, we have been proposing one more challenge:

- Explainability challenge: explain infeasibilities or alternative solutions.

The Winners

Winning entries from team led by Bernardino Romera Paredes with Kerry He from Hiverge won both the Scalability Deterministic and the Scalability Probabilistic challenge.

Winning entries from Linköping University team composed by Elliot Gestrin, Gustaf Söderholm, Paul Höft, Mauricio Salerno, Jendrik Seipp, and led by Daniel Gnad won the Explainability Challenge.

Entries from the team led by Jean Jodeau that includes Léna Aix and Benoît Bompol, all part of the company Sia, have been awarded a special prize.

We would like to sincerely thank all those who registered and engaged with the initiative. We are aware that the level of difficulty was high, and we are grateful for the interest and attention the competition received.

Resources and Tools

All resources are available via the GitHub area, including:

- Data and Technical Documentation

- Training Benchmark Set

- Official Evaluator Web Service

- Web-service-based Evaluation System

- Python Web-Service Submission Template

- Toolkit for Instance Generation, Encoding, and Evaluation for the Beluga Challenge.

An innovative Competition Platform has been developed to assess not only the performance of analytical models, but also the effectiveness of the underlying methodologies.

Designed to support open-innovation workflows in the scientific community, the platform allows researchers and developers to benchmark, compare, and explain their approaches in a controlled and reproducible environment.

For further information—or to reuse the platform for other competitions—please contact Optit.

Competition Timeline

November 18th 2024 – January 19th 2025 – Preparation period: registration, collect data and requirements.

January 20 – April 6 2025 – Submission period.

April 7 – April 30 – 2025 – Evaluation and winner announcement

17 September 2025 – Award Ceremony